Lock makers don’t want us picking their locks and do several things to prevent it. The most common design element is “security pins”. Security pins are nothing more than standard pins with some kind of weird cut and are usually drivers (the upper pins). The cuts can be a groove, a series of grooves, varying diameters, angled cuts, or rounded parts. Fortunately, each of these types of pins transmits a unique “feel” to our tension wrench and pick, allowing us to identify, attack and defeat them.

Standard Pins

The most common pin found in locks is the standard pin. It’s the cheapest and easiest to make and has no security features. Standard pins are cylindrically shaped, with no grooves or serrations in the sides.

The most common pin found in locks is the standard pin. It’s the cheapest and easiest to make and has no security features. Standard pins are cylindrically shaped, with no grooves or serrations in the sides.

Oddly, this is the pin that gives new pickers the most difficulty because it has no consistent feedback. You know the lock contains standard pins if they simply slide into position and make a distinctive “click” when reaching the shear line.

Spool Pins

The most common security pins you’ll run across are “spools” given that name because they resemble a thread spool.

The most common security pins you’ll run across are “spools” given that name because they resemble a thread spool.

There’s a variation of the spool called a “mushroom” because its shaped like a mushroom. Both types of pins transmit a very specific signal when picking and give a distinct visual signal called a “false set”. Both types slide in the cylinders, disguising themselves as normal pins, at least until the cutaway part enters the shear line. Once you feel a spool enter the shear line your life got easier because picking spools and mushrooms is pretty straightforward once you get the hang of it.

False Set

A false set occurs when a reduced diameter pin enters the shear line and gets stuck. This is most commonly the center section of a spool or mushroom pin. When that occurs, the core will turn slightly, giving you the impression that the lock is opening, but it’ll stop turning when the center of the pin gets caught in the shear line. You know you have a false set when the key hole is no longer vertical, but offsets to one side. The amount of offset will depend on how narrow the middle of the pin is. The narrower the center of the pin, the deeper the false set, with “deeper” referring to the extent that the core rotates.

A false set occurs when a reduced diameter pin enters the shear line and gets stuck. This is most commonly the center section of a spool or mushroom pin. When that occurs, the core will turn slightly, giving you the impression that the lock is opening, but it’ll stop turning when the center of the pin gets caught in the shear line. You know you have a false set when the key hole is no longer vertical, but offsets to one side. The amount of offset will depend on how narrow the middle of the pin is. The narrower the center of the pin, the deeper the false set, with “deeper” referring to the extent that the core rotates.

To overcome a false set you first need to find which of the pins is causing it. Maintain moderate tension and move your pick from pin to pin, applying pressure on each as you move down the row of pins. When you apply pressure to the binding pin you’ll feel the lock core try to turn slightly. This is called “counter-rotation” and is unique to spools and mushroom pins. Keep applying pressure on the pin while slightly releasing tension on the core. Don’t release too much or all the pins will fall. I could go on about this but the fastest way for you to learn the technique is simply watch the video and you’ll be whipping them in no time. Well, after a little practice anyway.

.

Serrated Pins

Another type of security pin is a “serrated” design. There are several variations to this but in general there are grooves cut around the length of the pin.

Another type of security pin is a “serrated” design. There are several variations to this but in general there are grooves cut around the length of the pin.

The grooves are designed to grab along the cylinder walls and snag at the shear line – giving you the feedback indicating the pin is set, when it isn’t. The grooves may be narrow, wide, or a combination of both. Of all the different types of security pins, these are the nastiest to pick and require considerable practice to defeat. To save a lot of reading, just watch the video and you’ll shorten your learning curve considerably.

.

T-Pin

Another interesting pin that’s becoming more common is the T-pin. It looks like a spool with one end cut off.

Another interesting pin that’s becoming more common is the T-pin. It looks like a spool with one end cut off.

T-pins are used as drivers with the narrow end facing towards the key pin. When the narrow part hits the shear line you’ll get the characteristic false set. However, this pin will not give you the counter-rotation that spools and mushrooms do. They can be tricky to find but you know you have one stuck in the shear line when you have a deep false set and get no feedback from any of the pins. At that point, lighten up on your tension and apply pressure only to pins that you know you have not yet set. The T-pin will teach you how to keep a mental map of the lock you are picking. If you don’t, you’ll have plenty of time to practice because you’ll end up oversetting one of the other pins while searching for the T-pin. Nasty little suckers.

Information added by Igor Petrusky: While the T pin is used by tricksters like us to pin up challenge locks, originally it was invented by Schlage as anti-bump measure. The narrow end goes inside the spring and when the bump key strikes the key pin the momentum is transferred through the driver pin to the T-pin, shooting the T-pin with the spring up and leaving the driver at the shear line. That was the original idea, but since then the T-pins are used by the lock sport community as trick pins.

.

Mixed Design Security Pins

Some designers combine different features into a single pin. A few years ago American Lock Company began using only spools with serrations on each end. These first give the indication of a serrated pin (which you always assume with American Brand locks because it’s their trademark), then give you a dramatic false set – leaving you wondering “what the hell just happened?” Still other manufacturers combine serrated, spool AND reduced diameters, like these Assa pins. These will keep you on your toes! The “old style” pins are on the left and the newer, tougher to pick Assa pins are on the right.

Some designers combine different features into a single pin. A few years ago American Lock Company began using only spools with serrations on each end. These first give the indication of a serrated pin (which you always assume with American Brand locks because it’s their trademark), then give you a dramatic false set – leaving you wondering “what the hell just happened?” Still other manufacturers combine serrated, spool AND reduced diameters, like these Assa pins. These will keep you on your toes! The “old style” pins are on the left and the newer, tougher to pick Assa pins are on the right.

Assa also “counter-mills” the pin chambers to catch those protrusions on the pins. Counter-milling is nothing more than undercutting the core chamber, leaving a “lip”. The lip snags the grooves on the pins, effectively locking up the core and bible. Since they are bound up by the tension you are placing on the core, it provides very little feedback to you. In effect, the core goes “dead”, meaning it gives no feedback.

Key Pin Trickery

Oh yeah, in case I neglected to mention it, even KEYPINS can incorporate these features. These are standard high security key pins. Other manufacturers use spools, tapers, or a combination of all of these. Just when you thought it was getting easy, right?

Oh yeah, in case I neglected to mention it, even KEYPINS can incorporate these features. These are standard high security key pins. Other manufacturers use spools, tapers, or a combination of all of these. Just when you thought it was getting easy, right?

Radical Bitting

Another anti-picking design involves varying the length of the key pins radically, resulting in an extreme “saw tooth” looking key. Locks pinned like this require some finesse to set the high cut pins in the back without oversetting the low cut one in front of it.

Another anti-picking design involves varying the length of the key pins radically, resulting in an extreme “saw tooth” looking key. Locks pinned like this require some finesse to set the high cut pins in the back without oversetting the low cut one in front of it.

This Primus key exhibits fairly radical bitting while also incorporating another anti-picking feature: a second locking mechanism parallel to the first. Both mechanisms are distinctly different; one is a standard 6-pin tumbler, which may or may not contain security pins.

This Primus key exhibits fairly radical bitting while also incorporating another anti-picking feature: a second locking mechanism parallel to the first. Both mechanisms are distinctly different; one is a standard 6-pin tumbler, which may or may not contain security pins.

The second mechanism consists of small sliding tabs that are not spring loaded and requiring supreme finesse to manipulate into place. Finally, the sliders control a side bar that must be fully retracted before the core will turn. The Primus is an awesome lock and is one of the most difficult locks to pick open.

Paracentric Keyways

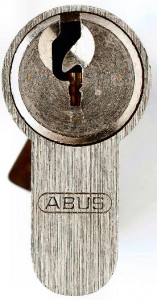

Weird pins aren’t the only way lock designers can mess with us. An extremely effective way to keep us from picking their pins is to prevent access to them altogether. This is called a “paracentric keyway” and is curved in such a way that our picks cannot fit into the keyway. Even when we manage to squeeze an undersized pick into the keyway, its pinched or dragging along the warding, making it nearly impossible to “feel” the pins or pick them. Locks made in North America are not known for paracentric keyways but in Europe and high security locks its routine.

This is an Abus TSB-5000 and has one of the most paracentric keyways I have ever seen. If you look closely you can see the pins actually resting on the shelf of warding, so any low cut pins are automatically over set when you put your pick into the keyway.

Photo courtesy of Dirk Beumer and the lock belongs to Adrian Weber, one of the biggest lock collectors in Germany.